Crude oil is one of the most valuable, naturally occurring materials in the world today. A continuous supply of this valuable natural resource is secured by drilling deep into the earth. Once brought to the surface, industrial companies in the oil and gas industry refine and distill this oil to create a wide range of useful products.

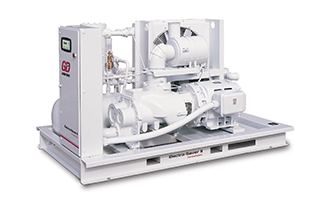

Industrial air compressors are ubiquitous within these environments as versatile pieces of equipment with a wide range of uses. They are vital pieces of equipment in the oil and gas industry that supply a steady flow of compressed air that powers various other equipment. In addition to their functionality, industrial air compressors also feature durability and longevity, handling the high demands of the industry’s many challenging applications.

This blog looks at four critical applications of industrial air for petroleum industries, the most common uses of industrial compressors for the oil and gas industry and the future of compressors within the industry.

Four Critical Applications in the Oil and Gas Industry Requiring Compressed Air

The oil and gas industry is responsible for exploring, extracting, refining, and transporting fossil fuels all over the world. Compressors for Oil and gas industry play a crucial role across critical operations as they power a wide range of equipment, including the following:

Onshore and Offshore Drilling

Air compression is needed for both onshore and offshore drilling. The amount of air pressure required for these drilling situations will depend on the size, depth, and composition of the earth being drilled.

- Onshore Drilling – encompasses drilling operations to gain access to underground oil sources in in-land settings. These operations can be accomplished by a small team with a small rig and one compressor for oil industry processes with a spread of about 24,000 SCFM or more.

- Offshore Drilling – refers to complex drilling operations in order to penetrate the seabed to extract oil and gas. Unlike onshore drilling operations, offshore drilling requires specialized equipment in order to withstand the harsh marine environment, such as an offshore rig equipped with industrial compressors for oil and gas industry operations.

Gas Compression

Gas compression operations are crucial in the oil and gas industry, serving a myriad of applications essential for the safe and efficient extraction, transportation, and storage of hydrocarbons. Industrial air compressors enhance oil recovery by maintaining reservoir pressure and driving the oil towards production wells.

Gas ends are a crucial component of drilling and equipment packages used in companies that deal with a package system. They are responsible for managing large volumes of various types of natural gasses, especially during the vapor recovery process, such as sweet or sour natural gasses, helium, ammonia, biogas, and so on.

These gas ends have a wide range of applications, including vapor recovery, landfill gas, fuel gas boosting, and wellhead boosting. To meet this demand, manufacturers of industrial air compressors offer a range of rotary screw gas ends that can handle different capacities and horsepower ranges.

Pipeline and Process Services (PPS)

The oil and gas industry’s pipeline and process services (PPS) rely heavily on industrial air compressors. These compression systems operate in harsh and hot environments, which means their reliability is crucial. They play a pivotal role in ensuring the efficiency and integrity of PPS’s complex components.

Within this very specialized market sector, industrial air compressors are not just mere tools. They are indispensable assets that facilitate essential compression processes critical to the seamless functioning of pipelines and intricate industrial operations.

The demand for reliable air compressors in this sector arises from the need for unwavering performance in conditions where durability and dependability are non-negotiable prerequisites for success.

Well Testing

When it comes to testing oil wells in harsh offshore conditions, reliable equipment is essential. An important component for such operations is the industrial air compressor. These compressors provide high-performance compressed air that is crucial for various tasks during the well testing phase, such as well clean-up, flowback, and data acquisition.

The industry relies heavily on air compressors to power pneumatic tools, control valves, and other important instruments for accurate data collection. It can be challenging to find compressors that are powerful and efficient while also being compact enough to fit within the limited space available on offshore platforms.

Additionally, these compressors must meet the rigorous demands of offshore operations, ensuring safety, reliability, and flawless functionality throughout the well testing process.

The Most Common Uses of Industrial Air Compressors within the Industry

Playing a big role in the oil and gas industry, some of the most common applications of industrial air compressors include:

- Petroleum Refining – 95% of petroleum gas is processed through compression before transporting it in a pipeline.

- Petrochemical Synthesis – Manufacturing ammonia, methanol, urea, ethylene, ethylene glycol, and other petrochemicals require particular air and gas pressurization.

- Gas Re-injection in Oil Fields – A series of compressors can be used for gas or re-injection for maintaining reservoir pressures and facilitating the recovery of crude oil

- Pipeline Transportation – Reservoir pressures gradually decrease over time, so compressors are needed to maintain or boost gas flow into the pipeline system.

The Future of Industrial Air Compressors in the Oil and Gas Industry

The industry can expect an increase in the demand for industrial air compressors over the next few years. And although there have been great strides in the development of alternative sources of energy, the majority of the population will still have to use petroleum as their primary source of energy.

According to the U.S. Energy Information Administration, the United States alone used 20.01 million barrels of petroleum per day in 2022. This is up 1.2% from its average daily consumption the previous year.

And with regards to access to compressors for the industry, fierce competition will lead to the development of more advanced machines to bring about easier access and larger yields to the industry.

How Can Fitz Equipment Help?

If you are looking for advice on new industrial equipment and industrial air compressors that are best for your business or the servicing of air compressors and torque converters, contact Fitz Equipment.

With over 50 years of dependable, fast, and friendly service, Fitz Equipment manufactures parts for torque converters and specialty machine parts. Fitz Equipment may have expanded, but one thing hasn’t changed. It is still a family-owned business with a commitment to superior customer service.

Leave a Reply